Katazome/ stencil resist print is a nice way to make pattern on indigo print fabric. As Indigo color fixes when it oxidizes, when there is something that prevents oxygen to touch the surface, this part does not get dyed and remain white (or the color of the base fabric). The Katanori paste is a rice flour based glue that you can apply on a fabric to prevent the air to touch the fabric surface so the part the glue is printed remain undyed.

For middle Europe traditional Blaudruck, the print pattern is made with similar idea. Instead of stencil, the patterns are applied with the block print technique. The resist material is called papp, and it is often a secret recipe… although secret, one of the ingredients are copper sulfate which is toxic. So it is not very desirable to use, especially with fermentation vat. At Zeugfärberei in Austria, they make their own papp resist with rice flour, rice bran and many more ingredients without toxic materials. As they use the iron sulfate indigo bath, the Zeugfärberei papp is adjusted to fit their vat.

Chinese katazome with indigo is called 藍印花布 and they use calk with soy flour as resist paste. I tried this once with others at the Zeugfärberei, and although it makes a very good stable resist paste that does not come off in the vat, it is also super difficult to remove it after dyeing. It has to be scraped off when dried after dyeing and washing.

The Japanese traditional resist paste is made of sticky rice flour and rice bran, water and salt with some calk (for indigo vat use). I tried cooking this with Janina from Zeugfärberei and we never really succeeded in getting a good paste. But now, I found few recipe on internet and on a book and I have it work now.

here are some resources:

- Otemae University tutorial

- Tanaka Nao natural dye shop tutorial

- Aikuma dye shop tutorial

- and this book Journeys in Natural Dyeing has a nice recipe

Here, I document the recipe I cooked my katazome paste. It was a mix of few recipes with some modification.

- Sticky Rice flour 30g

- Rice bran 20g

- water 60g? (adjusting when mixing)

- salt 2.5g

- calk 2g (mixed with hot water and only use the clear water above)

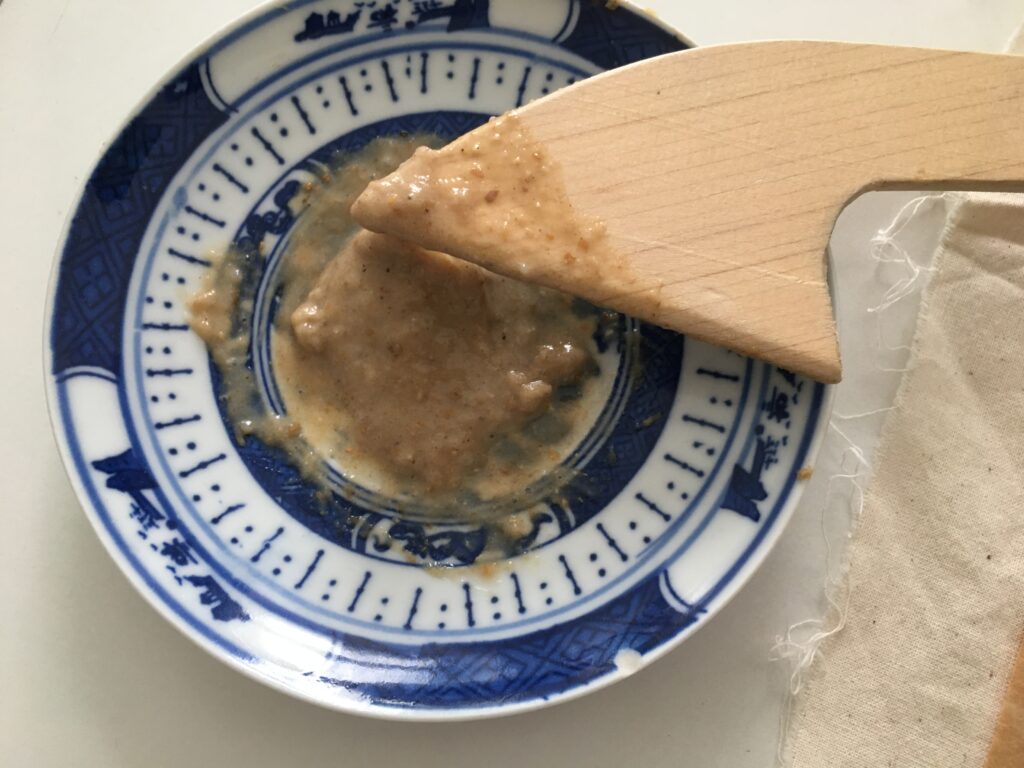

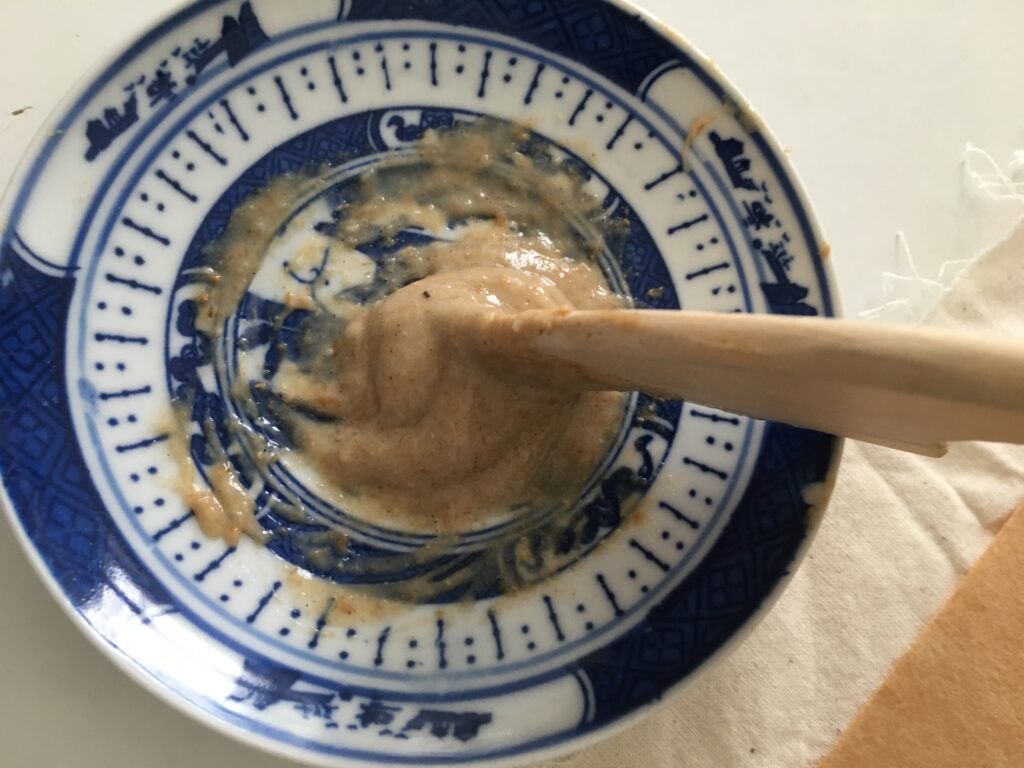

First rice flour and bran is mixed, then add water until it is mixed well (it is better to keep it quite on the dry side than wet dough) I also mixed the salt in the water so it mixes well. Then shape it in doughnut shape and steam it for 40min. After it is cooked, place it in a bowl and mush it well while it is hot. At this time, add warm/hot water and calk water to loosen the paste. When the paste is in good pasty, sticky consistency, store it in a jar, add extra salt water on the top so it does not rot nor dry and keep it in a fridge. I kept mine over 1 month in a fridge, and although at the point of 1 month, you could smell a bit, it was still usable.

When printing with the stencil, take it out of the fridge and let it warm up a bit. Add extra water if it is too hard and mix it well before printing.

Rice bran (糠) is something very common in Japan. It is a byproduct of making rice and you can buy it very cheep in a super market. For print/dye use, they sell fine powdered Rice bran for more price… but one can also grind normal one at home with coffee mill machine. In Europe, rice bran is not common at all and I have hard time finding it. The one I have is from Zeugfärberei. They were nice to share some of their rice bran with me. They buy their rice bran which is sold as horse food, and it comes in a big package!

It will be good to find a good way to buy rice bran in Europe. Sticky rice flour is something you can find easily in Asian supermarket. It is the “green” package one.