At Furusyo Dye factory (古庄染工場), one of the artisan, Michiko Furusyo has kindly showed us the workspace and their küpe and explained us how to prepare different types of shibori, together with beautiful samples and rare shibori books as references.

This is their küpe. They also have 4 küpe as one group and each of them has a different state of indigo inside (some are younger, some are older). We dyed with the first one on the left, which is already 6 months old and is the first step küpe. She explained that the first dip is to bring the fabric to the Alkaly environment and it is not so much of a coloring yet.

At this factory, they do not remove the indigo bubble/flower when dying. She said, it is ok to remove it or not… but as we are dying small things, it is not necessary and if not necessary, she will not do the extra work of removing it. Yes, very practical! She also hangs a basket in the küpe and dying takes place in this basket. The bubbles are outside of the basket so it does not interfere with the fabric one is dying.

Dip the fabric in the küpe, shake it and massage it for a while to make sure all the fabric surface is introduced to the dye liquid. Then leave it there for 5 min.

Remove the fabric from the küpe, squeeze out extra liquid, spread the fabric and make sure all the surface is exposed to the air. Leave it outside for 10 min. Normally you will then dip the fabric for a second round…. But we got into talking (or mainly I, asking tons of questions) and we forgot to dip it again. So, we finished it with one dip in the workshop.

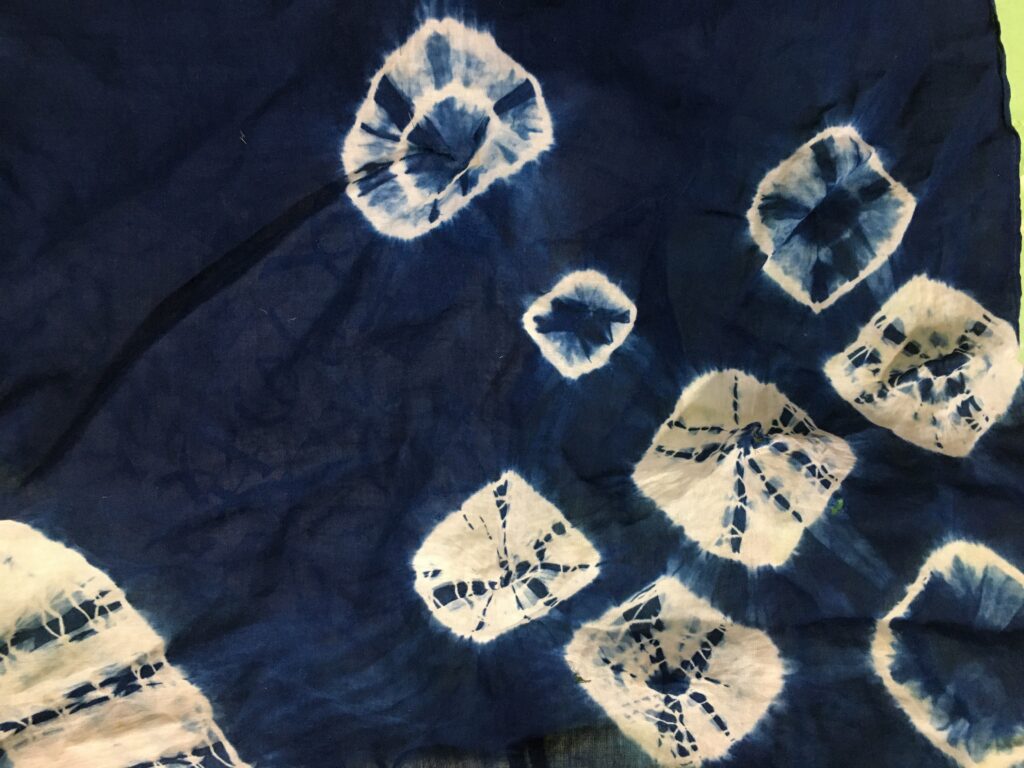

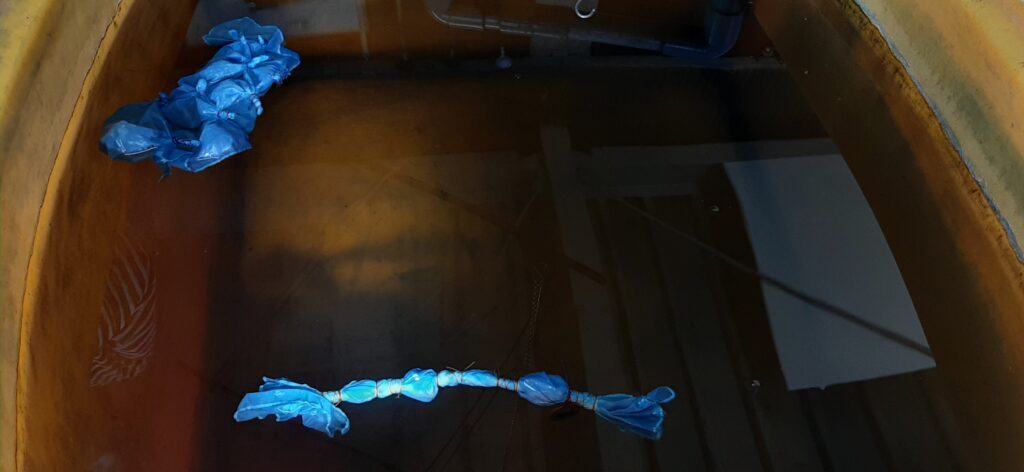

Afterwards, we let it swim in the water. The shibori thread stays on as this is not finished yet. This water process is to let the oxidation happen with water. (again, they do not only let the oxidation happen with air but use water. You can see the yellowness of the blue turns to blue in this process).

Michiko showed us her other work that was finished with the dye process and needed to be opened and washed. It was an Itazimeshibori (wooden plate shibori) scarf. You can see the yellow/greenness of the blue turning into deeper blue in the water.

Normally she will dip 3 times on each küpe, 5min-10min cycle. After that, the fabric is dipped in water and hung to dry (for shibori works, keep the shibori threads on). Next day (or several days later) when the fabric is dried, it is dipped in the second küpe and goes through 2-3 cycles of dye, then washed in water and hung for dry. She uses 3 küpe of different indigo states (I regret that we did not ask her to open the rid of all the küpe!) to finish the dye process. I expect the other küpe is fresher and is dyeing stronger than the one we saw.

We left our shibori fabric there, and she continued on dying with the 2nd and 3rd küpe and finished the dye process for us. When I received the finished fabric, I was astonished! It is dyed in beautiful deep indigo blue. I am impressed with her professional work. Knowing how tricky to get deep blue with indigo dye, it is really impressive work.