After cutting the stencil shape out of snap pap, we glue the screen with textile silkscreen paint. This process also make the snap pap surface water resistive.

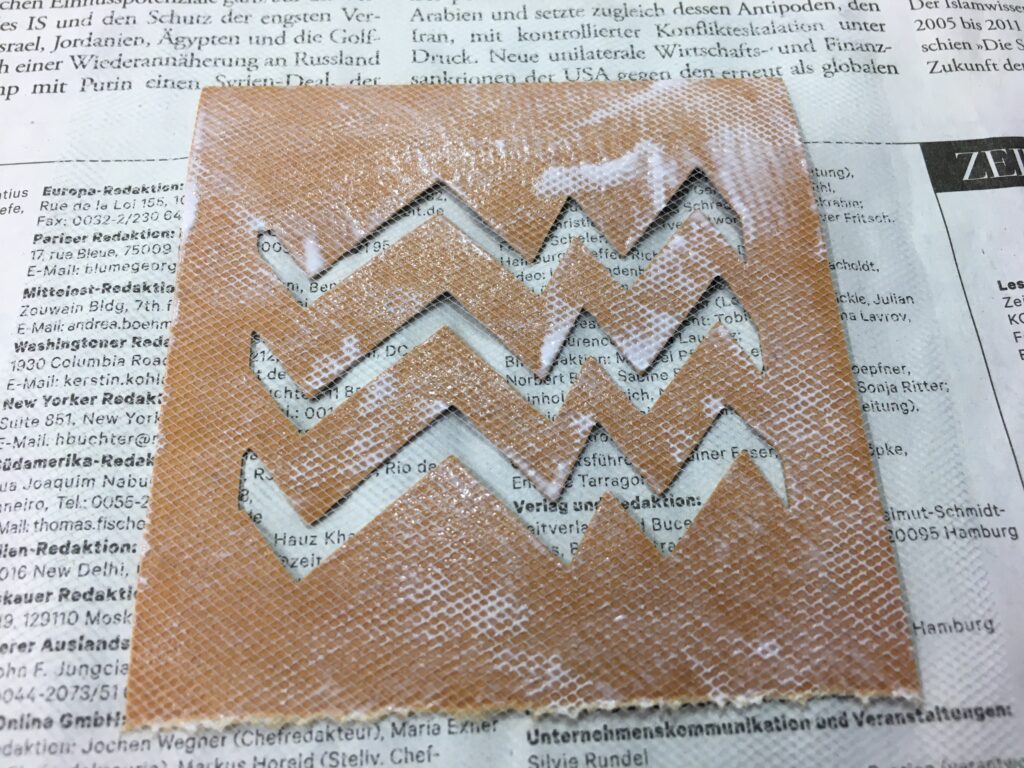

1 ) Place the stencil on newspaper (or surface that can get dirty). Cut off the mosquito net (or silkscreen net 16) slightly bigger than the stencil size. Iron the screen to make sure there are no wrinkles.

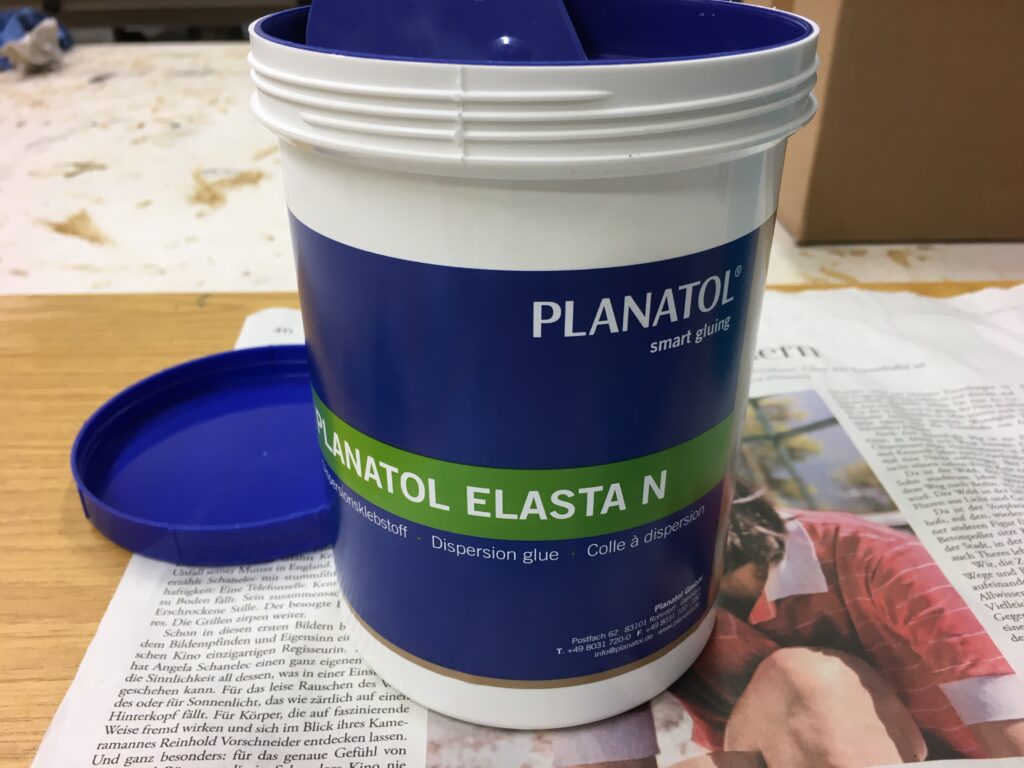

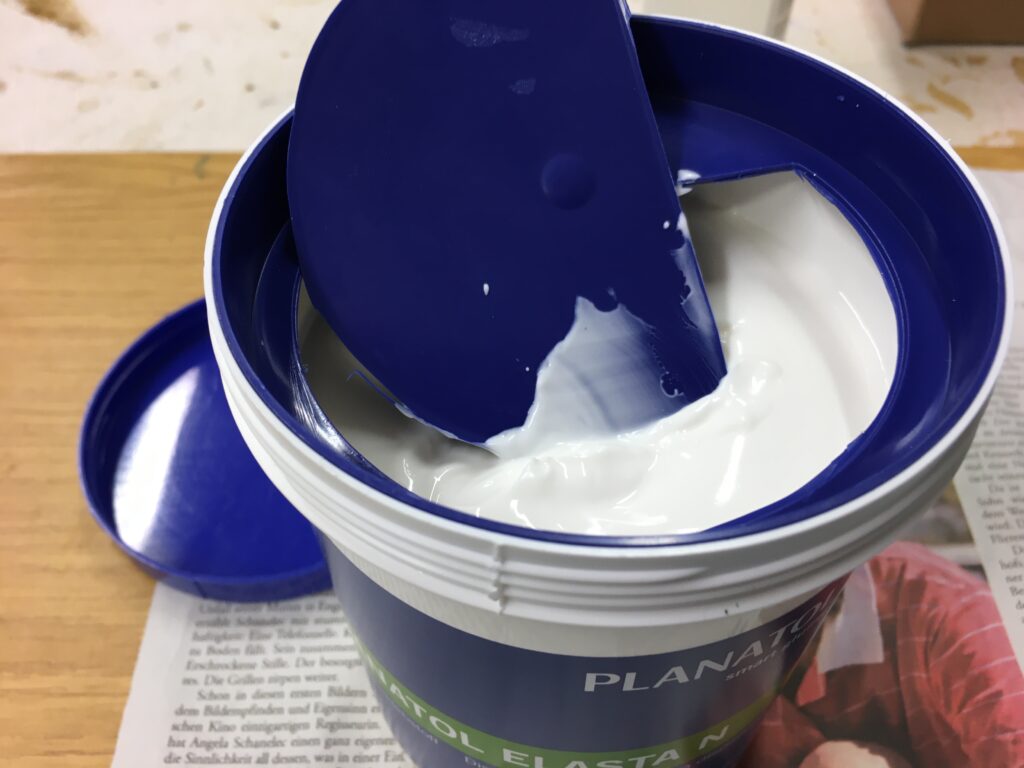

2 ) Apply water based glue on the stencil surface. I use Planatol Elasta N glue. It is good to use water based/ resolvable glue so you can remove extra glue on the net later easily. I use hard rubber roller to apply the glue evenly on the stencil surface.

3 ) After applying the glue evenly on the surface, check placement of the stencil parts, then gently place the net/screen over the surface. Adjust the screen to make sure there are no wrinkles and evenly distributed on the stencil. It is even good if there are slight tensions on each directions on the screen. Press the screen down to the stencil with fingers to make sure they stick well. This process is to pre-fix the screen on the stencil.

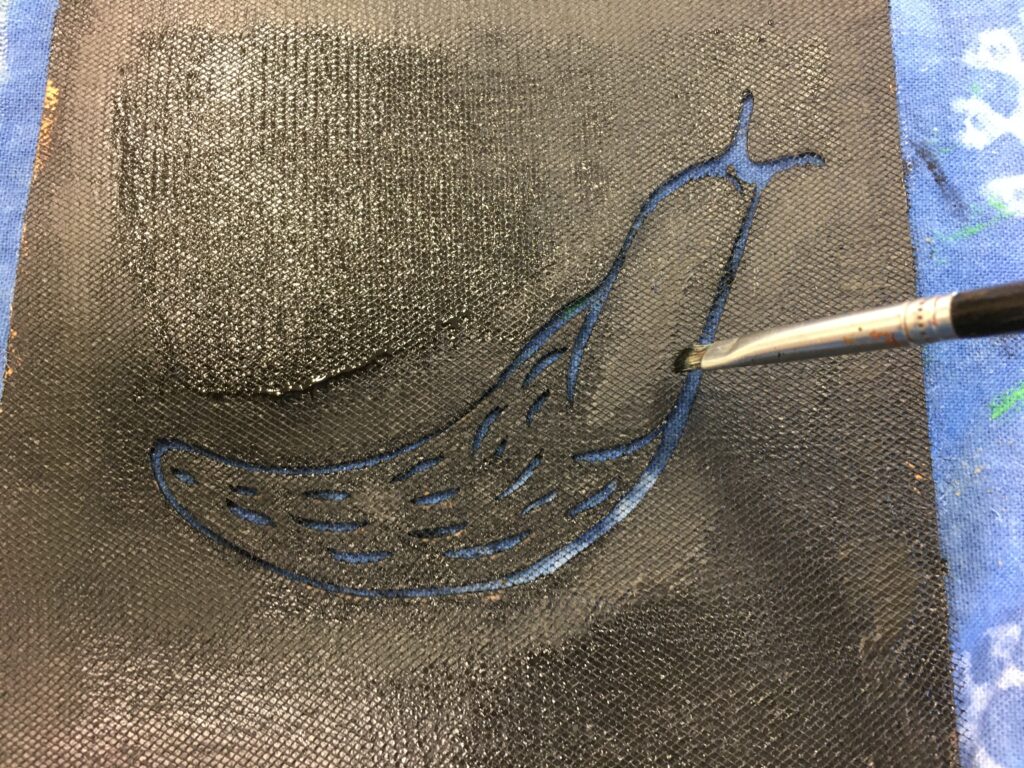

4 ) Wait until the glue is completely dry. Check if there are no excess glue on the net. If so, use small brush and water to remove it.

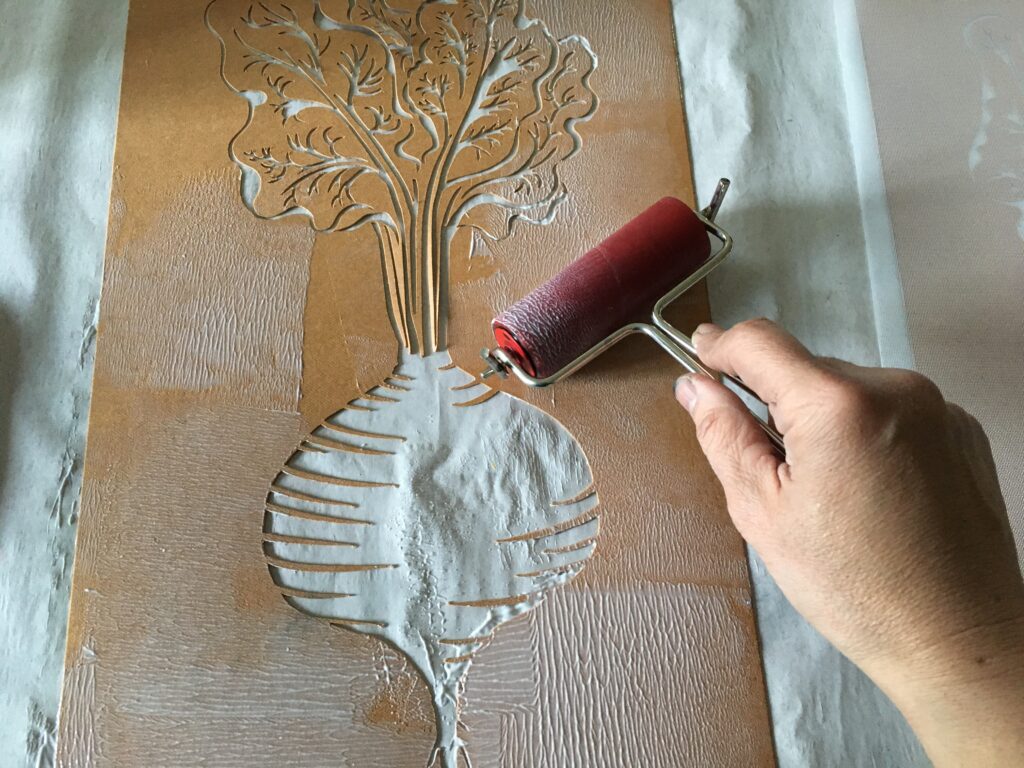

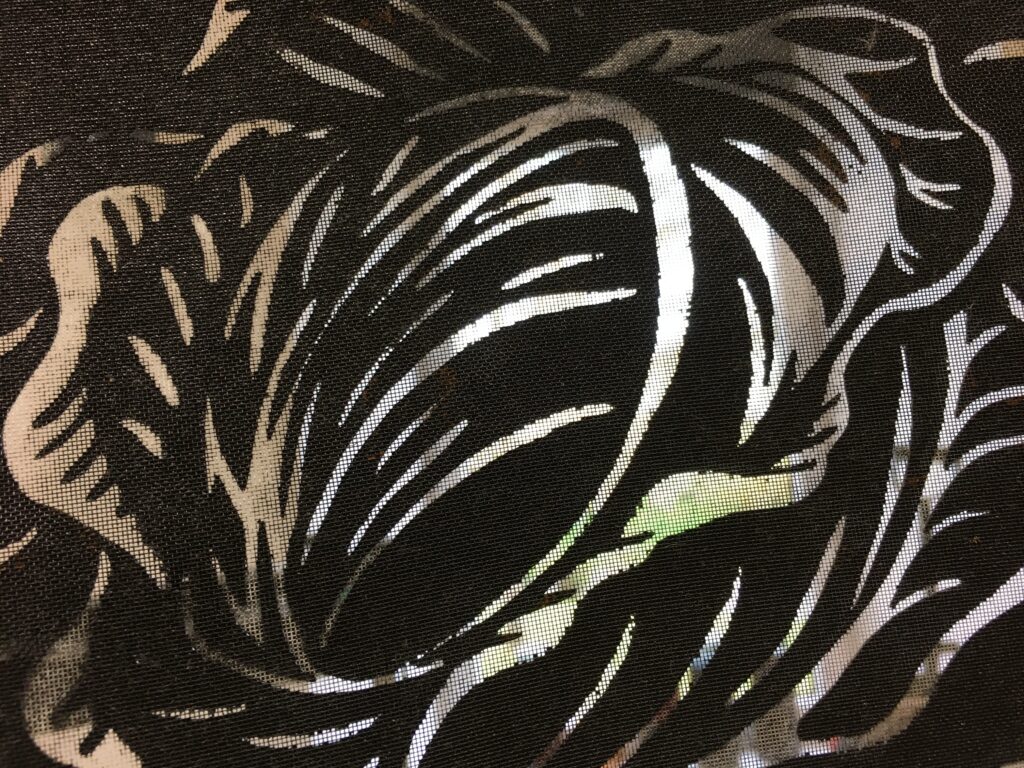

5 ) Prepare the paint on a straight surface (i.e. glass plate) The paint I am using here is a Textiel silkscreen color (TEXPRINT-AQ from www.siebdruck-versand.de). Dip the hard rubber roller into the paint, even it enough on the glass surface so the paint is evenly applied on the roller, then paint the stencil from net applied side. Apply the paint until the surface is completely colored. This takes a bit of time but do it patiently.

6) After finishing painting, let it set a side and dry it. When it is half dry, check the screen if it has excess paint on it. If so, use water and small brush to clean it. If it is completely dried already and does not come off with water, use acetone to remove paints.

7 ) Let it dry completely over night. Then apply heat on heat press to fix the paint. I use 160 degrees for 120 seconds. (it may differ with paint and screen you are using, please test with small piece first) I use reusable baking paper sheet on both side to protect the surface from directly touching the heat press surface. Cut off the extra screen material from the edge.

8 ) I painted other side (not net side) also with the textile paint and fixed it with heat press (160 degrees, 120sec) when it is dry to make both side water resistant. This step to paint both side is to prevent snap pap from curling up when it is wet. Although I am not sure how much positive affects it has to paint both side. Perhaps one can skip this step.

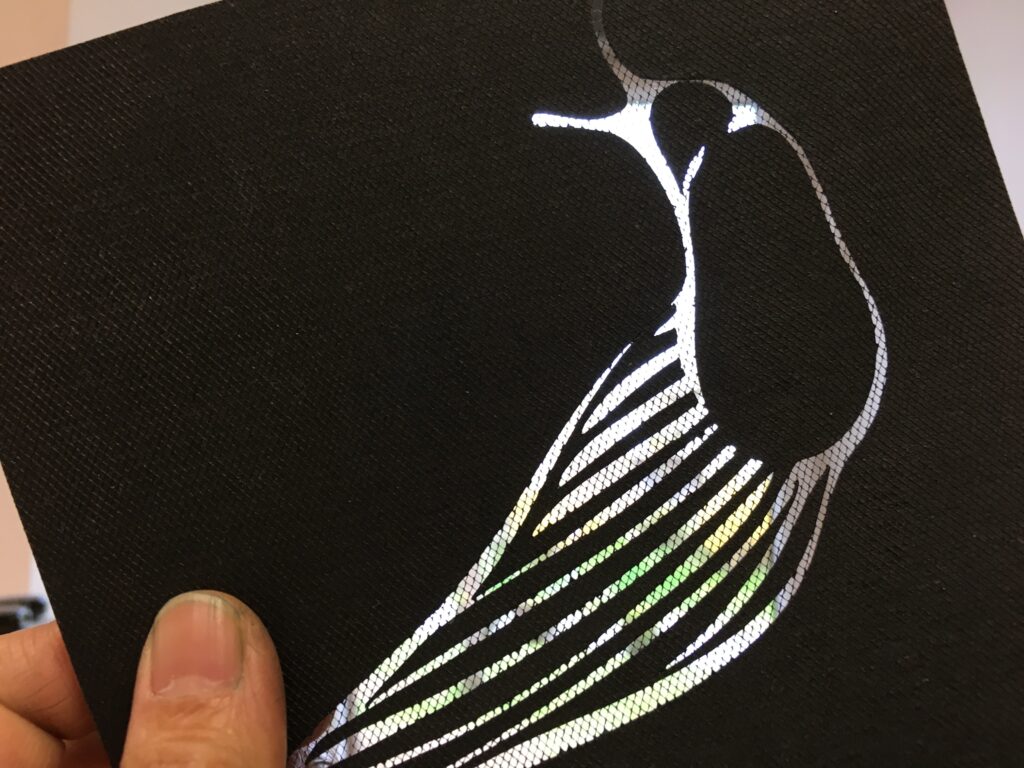

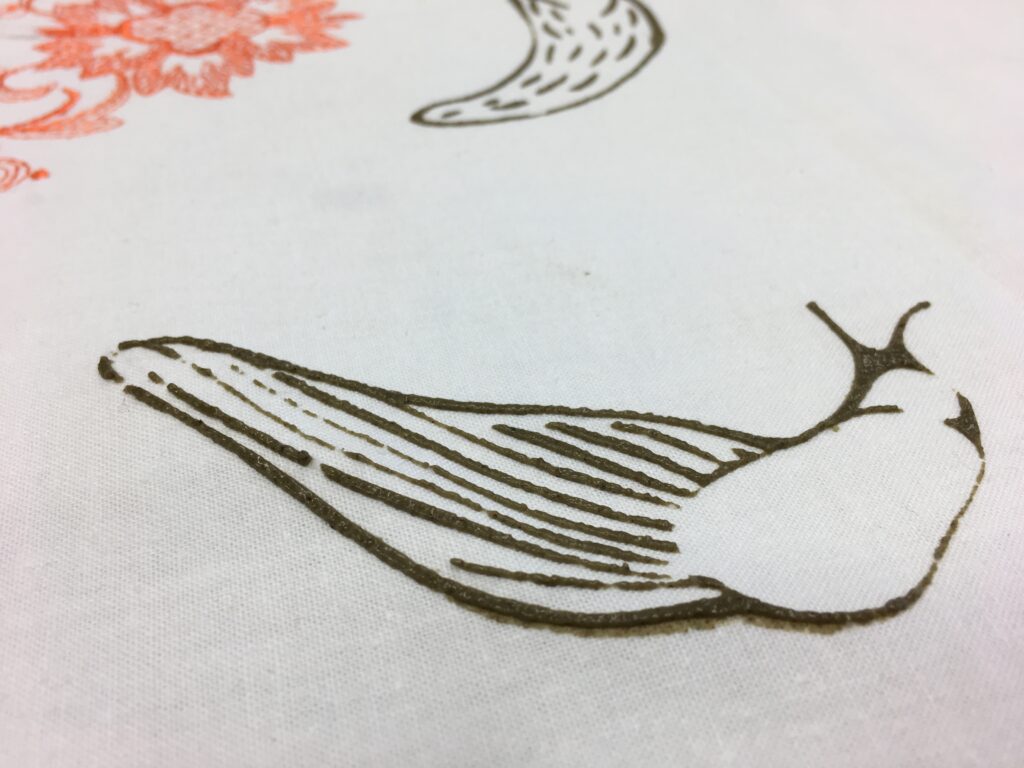

9 ) When both sides are painted and fixed with heat, it is ready to be used as stencil to print papp on fabric. Make sure to place the stencil’s screen side facing up and apply papp from screen side.

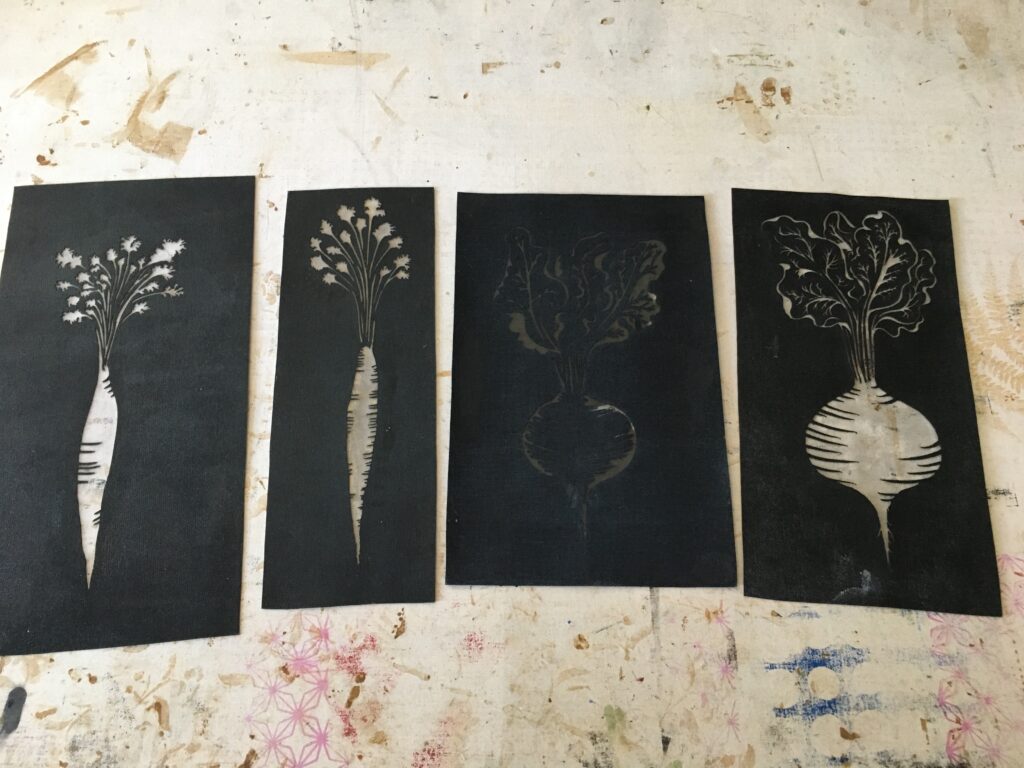

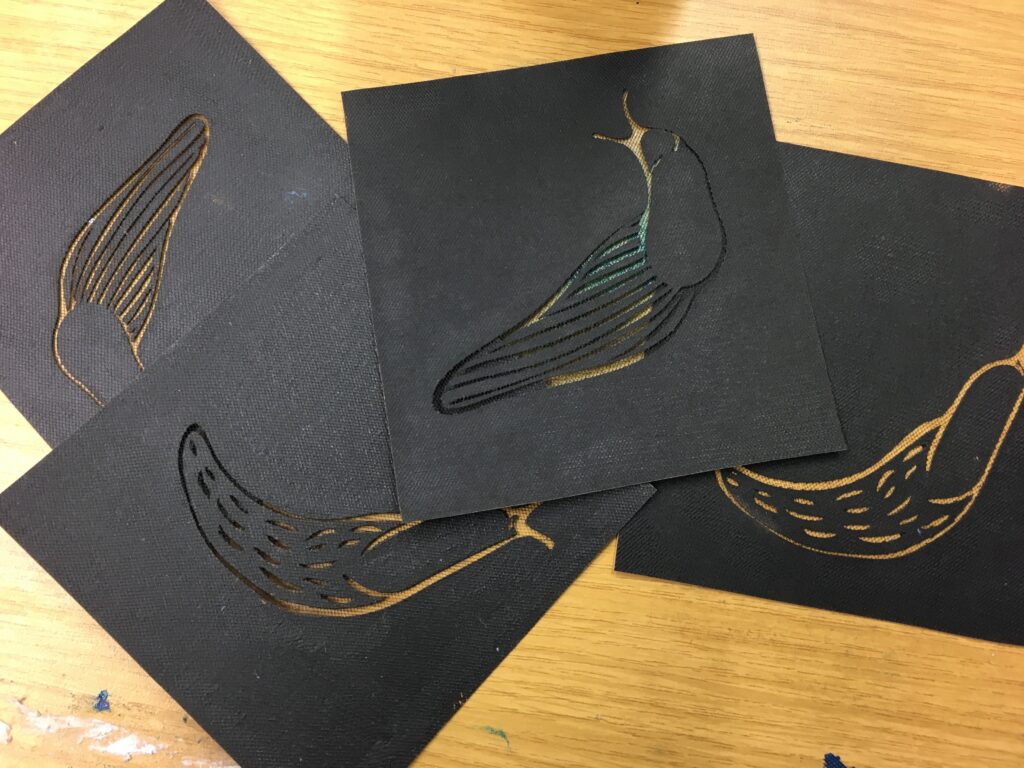

Here are the KATA stencils made for the project. .svg cut files are here >>