Indigo is a very interesting dying technique. Unlike other pigments, it does not color on its own. There are many plants that contain indigo, and one has to extract the indigo from the plants (for example fermenting the plants to extract). Indigo is insoluble and just releasing indigo in to liquid and dipping fabric will not fix the indigo color. Different regions have different techniques of making indigo dye bath. The technique used in Zeugfärberei currently is to reduce with ironsulfate in the bath with kalk to keep the pH high, then dying in the sequence of dipping and oxidation to fix the color on the fabric.

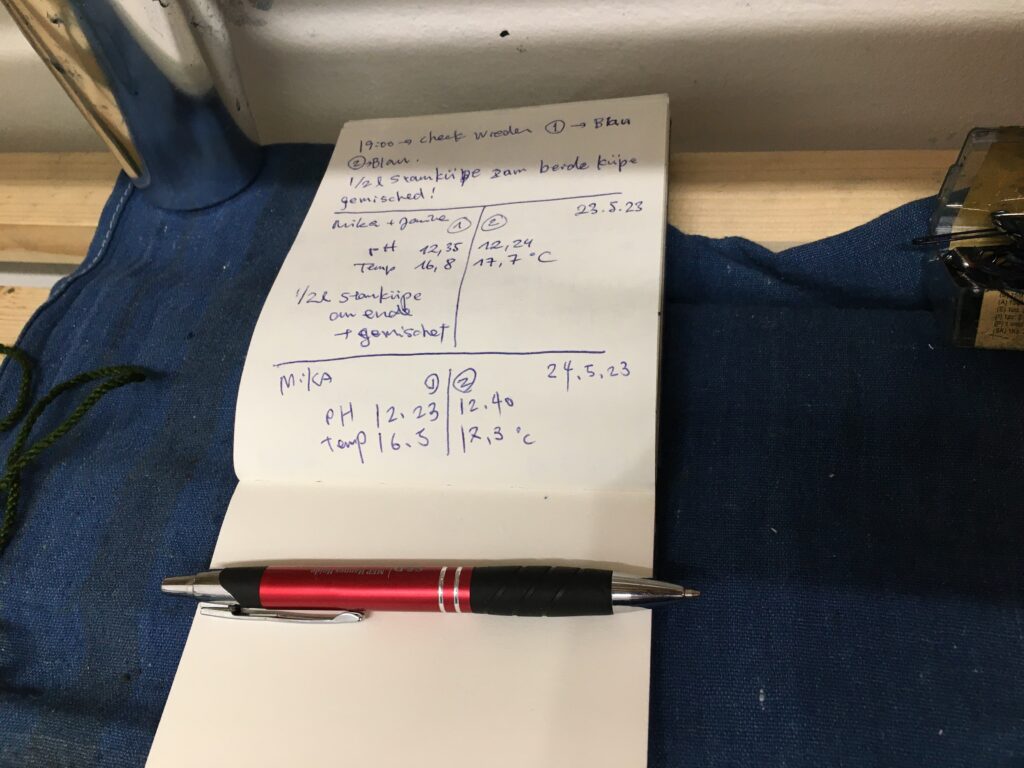

Each day, at the beginning of the day we check the pH and temperature of the küpe and make a test dye. It is interesting how they change everyday. And at the end of the day, we add eisensulfate or kalk to adjust the küpe environment. It effects many different element, and one can not just easily say “pH xxx is good”. Janina, who has been working with it for many years has a feeling of what one needs to do for the küpe. As you need clear küpe when you dye, and also chemicals need reaction time, you do not want to add things in the morning before dying. We add things at the end of the day, mix it well and hope that the next day küpe is healthy again. It is a bit of a rituals.

testing küpe. Dip these test strip fabric for 10 min. When it comes out, it is yellow-green and it quickly oxidase to blue. When you see the yellow-green strip on the end, is a good sign as the process is still going on the bottom where the liquid stays. The last photo is a comparison of küpe 1 and 2. Somehow 1 is always darker than the 2. I say Indigo soul sitting on küpe2 is a bit lazy than the küpe1 soul.

At the end of the day, one needs to mix the küpe so you can dye it again next day. By mixing, the indigo+kalk sediments that precipitated on the bottom of the Küpe is brought back in water again and gets reduced again. When mixing Stamküpe or extra Kalk or Eisen(II)sulfat, it is important that they are mixed well. To mix, you use this long wooden tool. First, stamp the bottom to move up the sediment into the water, then move the tool up and down quickly to create turbulence in water. It takes a bit of practice to be able to make the turbulence. The tool is quite big and heavy, and it is like a little sport at the end of the dyeing work day.