The “traditional” resist (what prevents indigo color to stay on fabric so you get white pattern) material called papp that is used in the region is a mix of gummy arabicum and copper sulfate and some other things ( that are usually the secret recipe that you can not know). As copper sulfate is poisoness when you wash it out directly to the draining system, and Zeugfäberei does not have special draining system to separate the poisoness waste water, Janina came up with papp that does not contain copper sulfate.

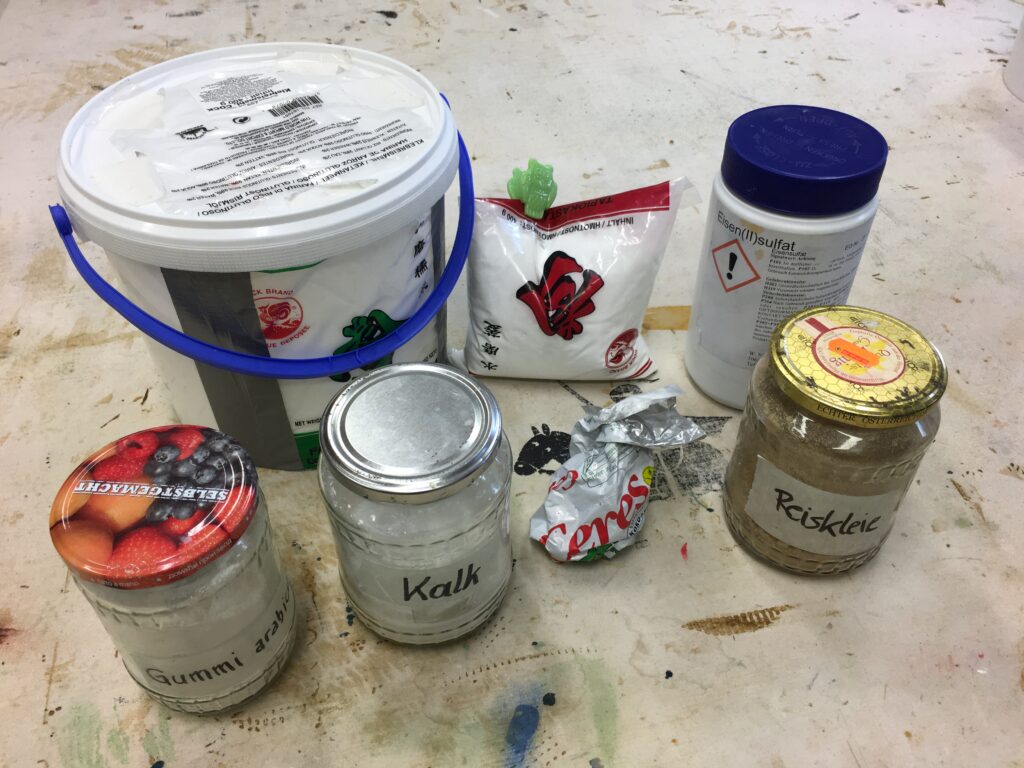

She made many research and experiments. Inspired by Bousen-Nori from Katazome technique in Japan, she uses Rice flour and Rice bran as a base. The Japanese recipes are basically just this two with water… but she went on to make more fine adjustment to suit to the küpe here. She adds also coconut oil, tapioka powder, gummi arabicum, eisen sulfate (this is not poisoness in small quantity) and kalk.

Rice bran (called Nuka) is a typical material in Japan as rice farming is very common and it is a by-product that are almost waste. Japanese use it to pickle vegetables, to wash pans, to soften bamboo shoots…

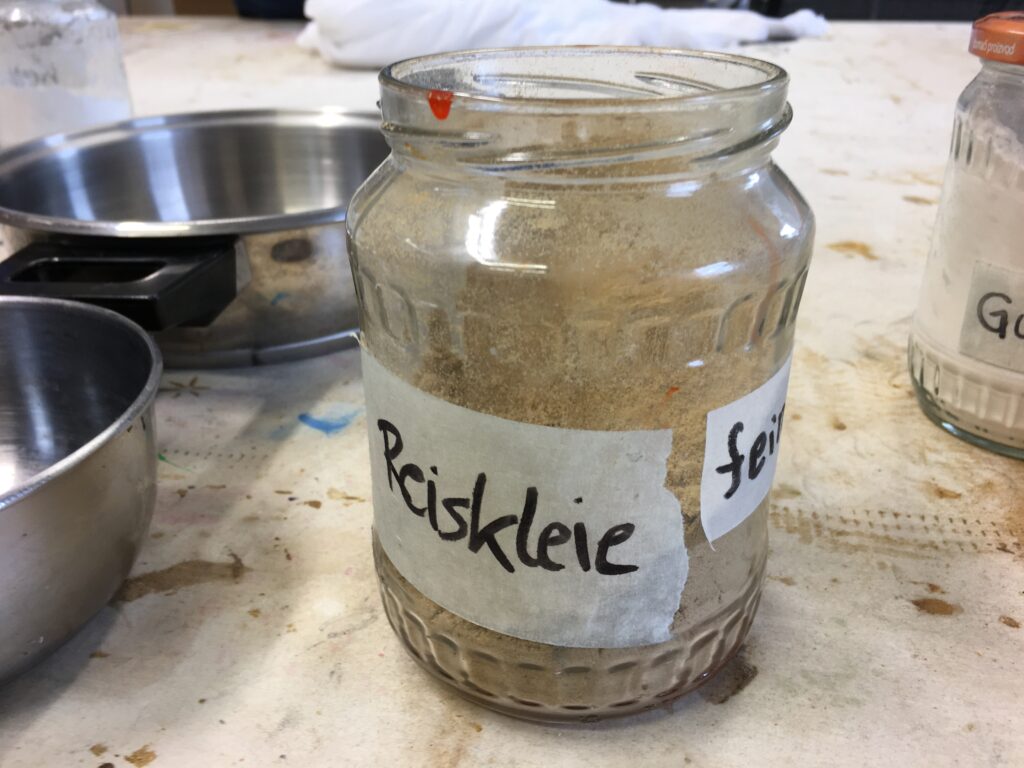

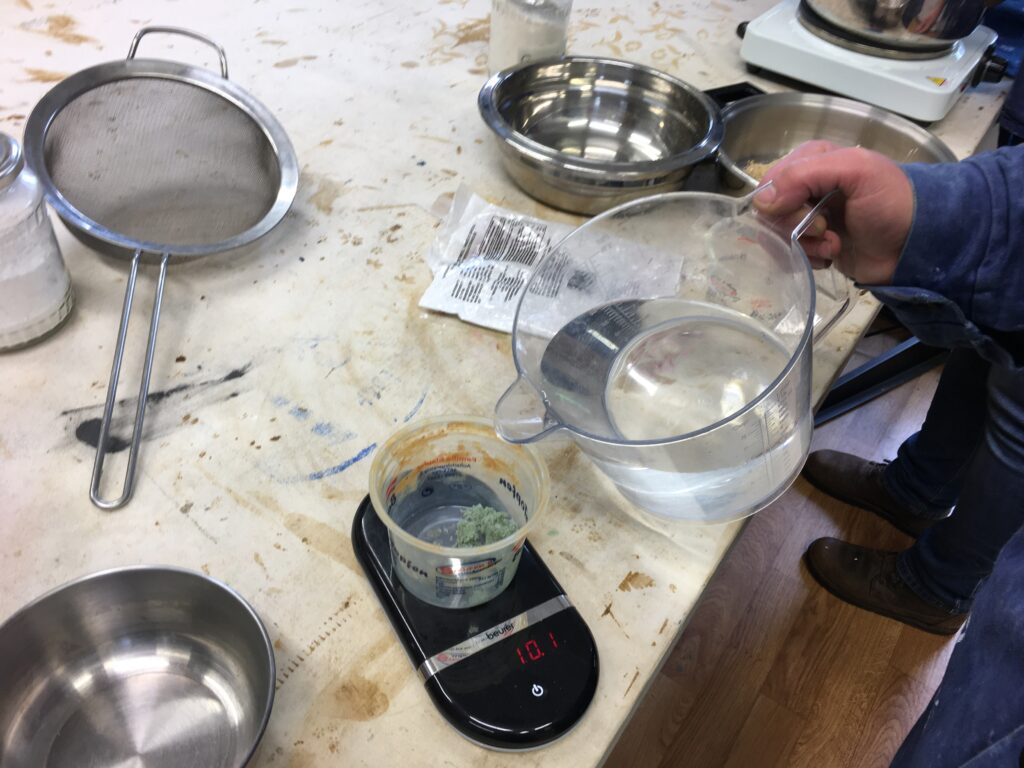

But in Europe, it is not a common material and it is not easy to obtain. Janina also tried other types of bran, like wheat bran, oat bran… but it does not work the same way. Then she found out that rice bran are sold in Europe as horse food! so now they buy this horse food bran, grained it extra fine, let it go through a strainer to get the perfect Nuka powder.

The papp/resist needs to match with the küpe you are using. This recipe may not work for other types of küpe. Janina said, when she was experimenting, she had an idea to add eisen sulfate in the papp as the küpe also contains it. This improved the resistance of the papp in the küpe much better (meaning it kept the fabric white where you applied). But if you have other mixture in your küpe it may not work the same way.

It looks like the recipe of the Papp/Resist travels and develops as the time goes. The Japanese got their recipe from Chine around 8th century, which originally was a mix of soy powder and kalk. The advantage of this mix is that it does not come out so easily and keep the pattern very white. But overtime in Japan it changed to rice bran and rice flour resist. They do not know exactly when and why the change happened… but one thing I can say from experimenting is that the mix of soy powder and kalk does not come out easily after dying when you want to wash them out. So, maybe it was a practicality. In China, they still use soy + Kalk as resist for indigo dye print process and they scrape the resist off after it is washed and dried. There are also technique to use wax as resist, called Batik and is still practiced widely in regions of Asia.

The Rice Bran (Reiskleie) sold here is not very fine. We use spice grinder to grind down to finer powder. We usually grind 5-6 times of 1.5minute cycle to make fine powder out of hourse food Reiskleie. The finer the powder is, the better for printing.

Here is the Papp recipe from Janina:

- 80g Rice Bran

- 60g Sticky Rice powder (green package one)

- 20g Tapioka powder

- 60g coconut oil

- 40g gummy arabicum mixed with 200ml water

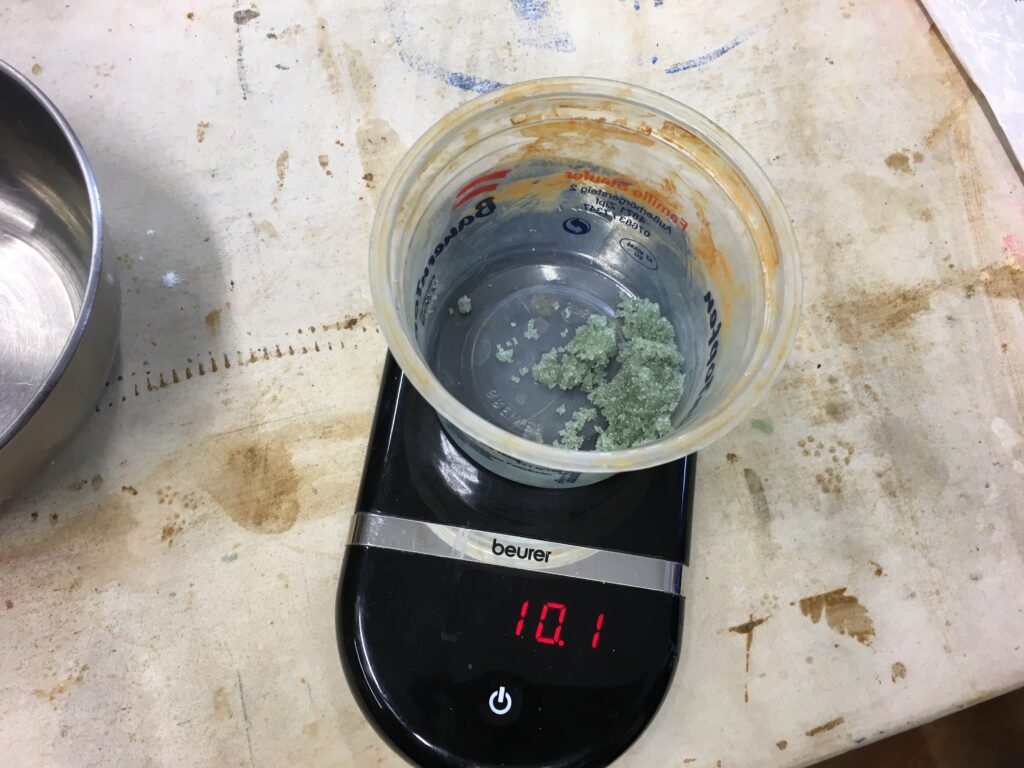

- 10g Eisen sulfate mixed with 20ml water

- 3g kalk mixed with 20ml water

- 300 ml water

and here is how to cook it:

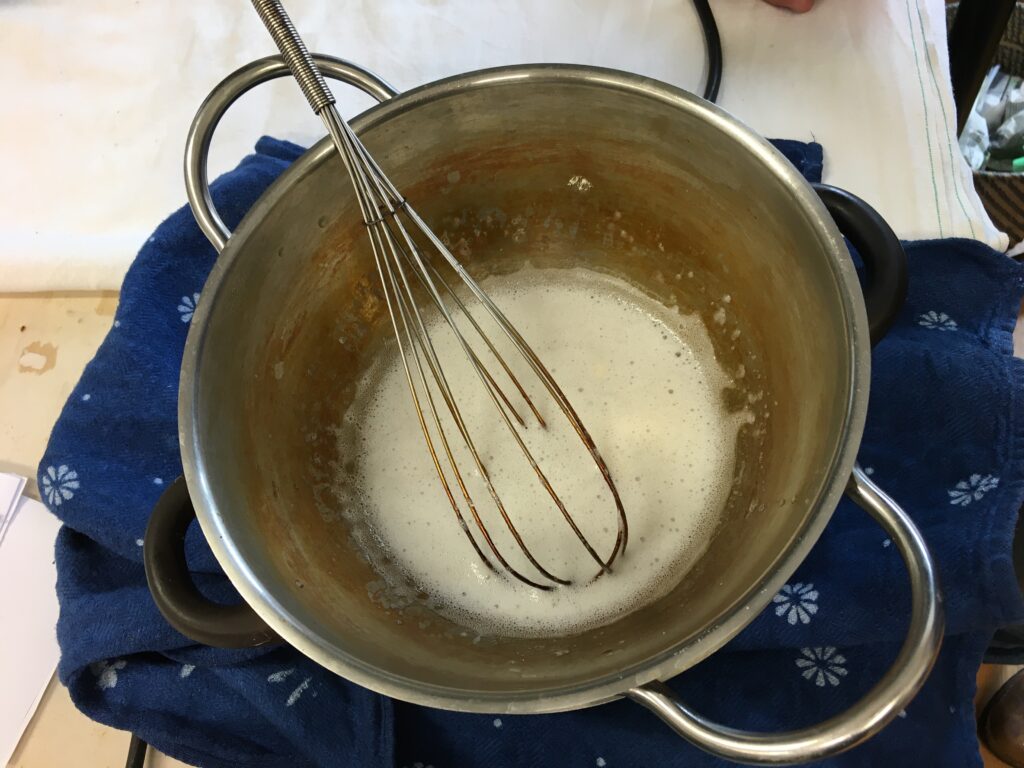

1: mix gummy arabicum and water in a bowl. cook hot water in a pan and dip the bowl to heat it up. mix it well. gummy arabicum becomes liquid when heated up. make sure there are not rumps.

2: Filter the prepared (ground in spice mill for 5-6 times, see above) rice bran. then mix the rice bran and rice flower, tapioka powder in a pan and roast it on heat. this is to prevent the microorganisms in the powder. When keeping the papp longer, these microogranisms could grow inside and let it go bad. If you are using up the papp right away, you probably do not need the roasging step.

3: Prepare the eisen sulfate and kalk mix. set it a side.

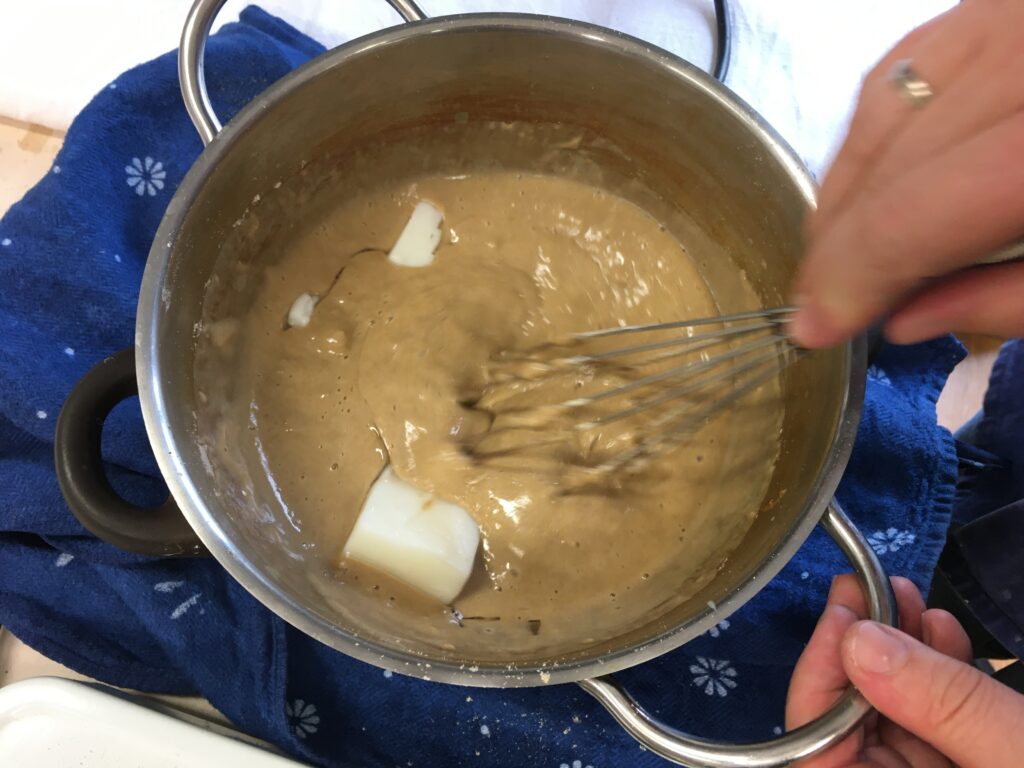

4: Put the Gummy Arabicum bowl with hot water pan back to the heat. Add 300ml water into it and mix it well. Then add powder mix (what was roasted earlier) into the bowl and mix it well. Then add the coconut oil. As the oil gets warmer, it becomes liquid and start to mix with the rest. keep mixing until the consistency becomes heavy and sticky. this is s the sign that the rice powder gets cooked.

5: When cooked, add the kalk liquid and mix it well. It makes the mix yellow and smells strange. but this is the reaction of the kalk and it is normal.

6: Then add eisen sulfate and mix it well again. this makes the mixture greenish color inside and dark brown outside.

That’s it! Move the mixture in container, let it cool. When it is cool, keep it in the fridge and will keep for a few weeks. When warm, the coconut oil is soft and consistency is a bit too loose for printing. so I usually let it sit in a fridge for a short while before using it for printing.