The Japanese Indigo (Persicaria tinctoria, 蓼藍) is often used as Sukumo, which is fermented leafs in Japan as indigo dye stuff. Persicaria tinctoria is a buckwheat plant family and grows in relatively cold weather, native in Asia and in eastern Europe.

Waza-no-Yakata is growing Persicaria tinctoria year-round in a LED chamber room so the visitors can see the plants at any time of the year. Otherwise it is a one-year plant and it grows between April-October.

Sukumo is a fermented Persicaria tinctoria leaves. In Japan, instead of making the indigo extract cakes/mud, like in India/China/Taiwan/Okinawa, they preserved indigo by fermenting. It also reduces the size for transportation of the dye stuff.

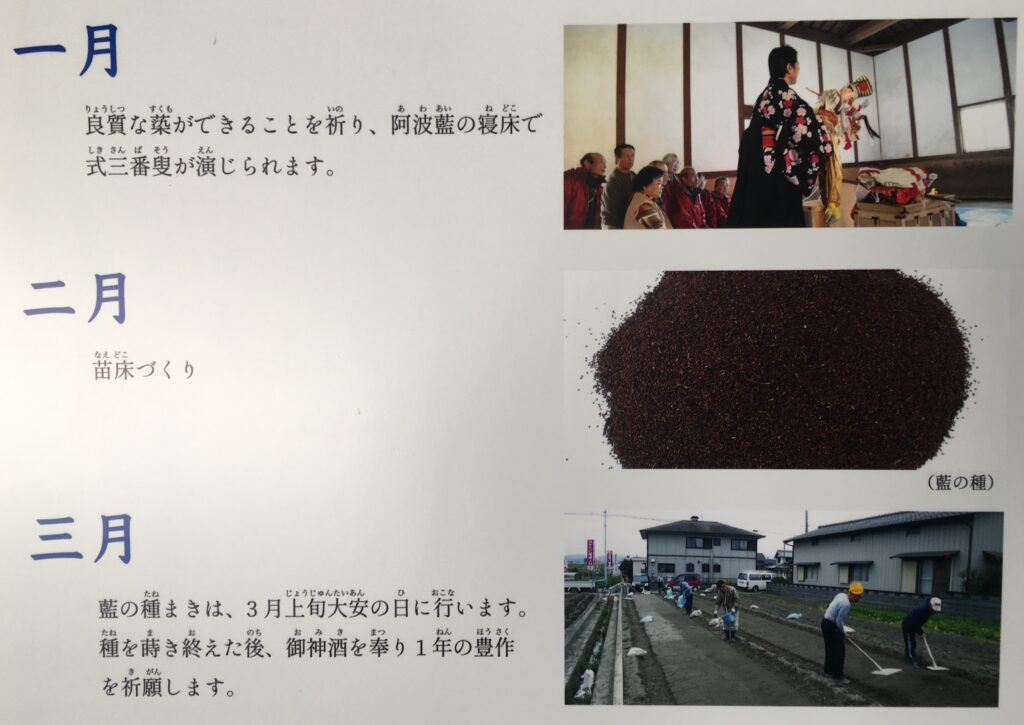

Sukumo Production Cycle

At Ai-no-yakata, they had a detailed explanation of how sukumo is made, from growing the plants to the fermentation process. They also exhibit the dioramas of the scenes from the old times production so we can imagine how it used to be to produce sukumos in the region.

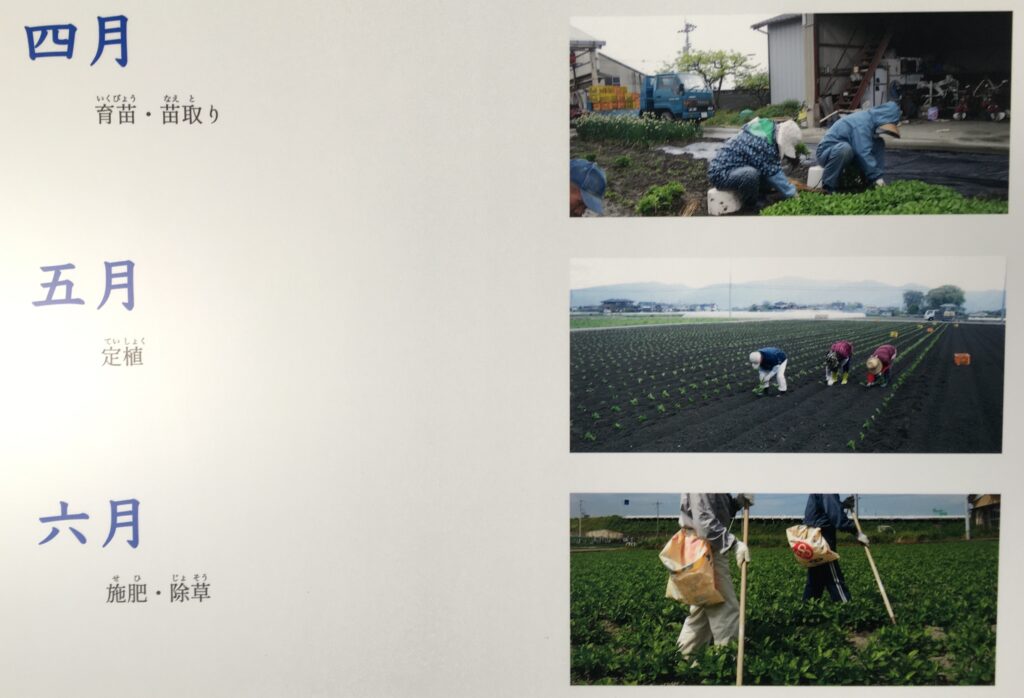

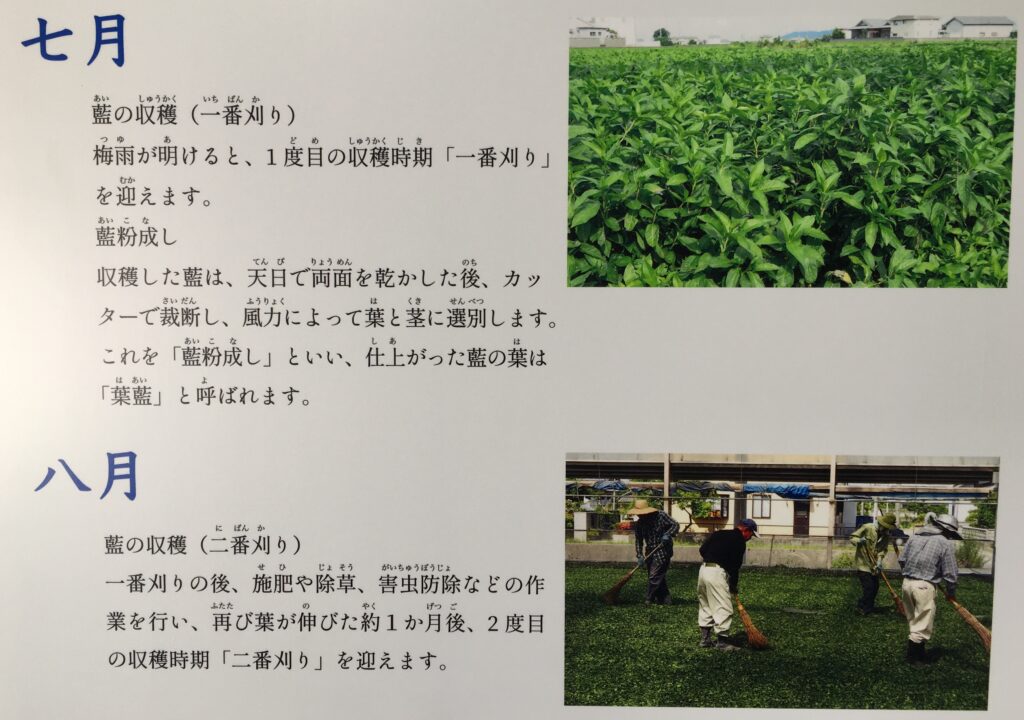

March: Seed planting. Seeds are planted at the beginning of March.

April: Raising/harvesting seedlings

May: Permanent Planting

June: Fertilization/weeding

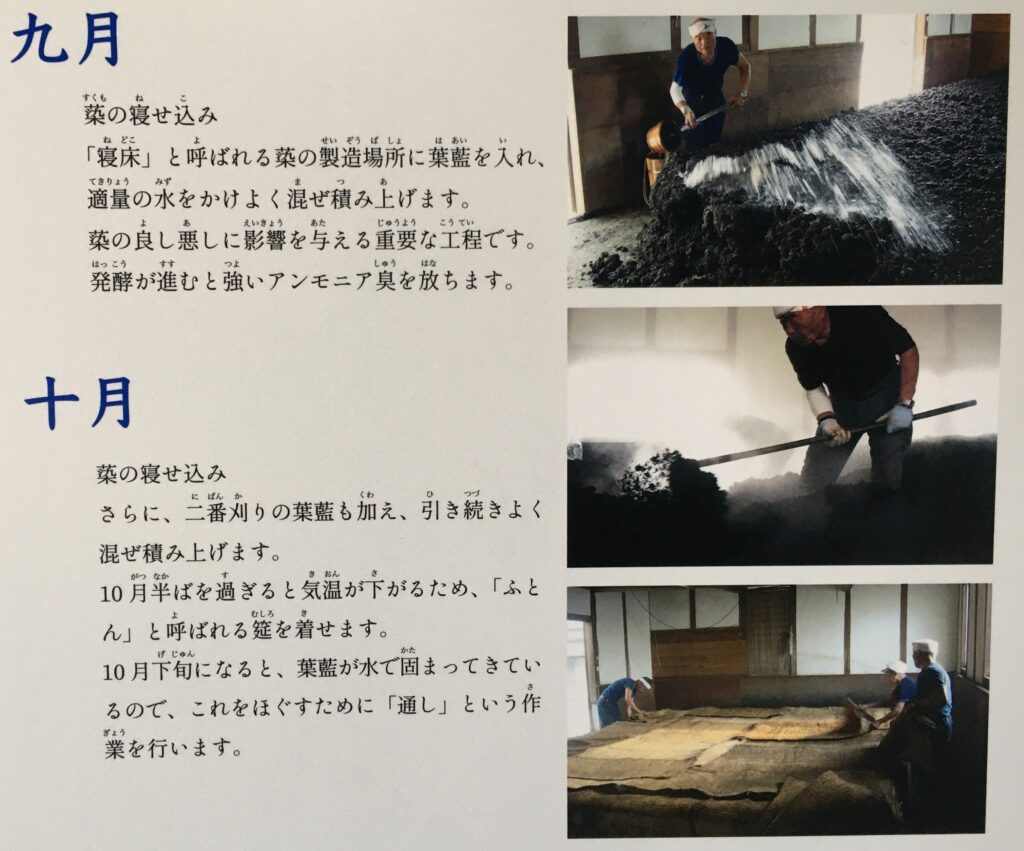

July: Indigo harvesting (first harvest). The first harvest period arrives when the rainy season is over. The harvested indigo is dried in the sun, cut and leaves are sorted from the stalks. This process is called “Ai-konashi”.

August: Indigo harvesting (second harvest). After the first harvest and fertilization, wedding, pest removal… the leaves are left to grow for about 1 month before harvesting the second time.

September: Sukumo-no-nekashikomi (start of sukumo fermentation). The dried indigo leaves are put in a sukumo production room (nedoko 寝床/sleeping room) and mixed well with a suitable amount of water. This is a vital part of the process which can impact the quality of the sukumo. As the fermentation proceeds there is a strong smell of ammonia.

October: The indigo leaves from the second harvest are also added, and it continues to be mixed once every 5-7 days. Ater mid-October, the temperature drops, so it is covered with a straw mat called “futon/blanket”. By the late October, the indigo leaves have started to solidify in the water so a sifting technique called “toshi” is performed.

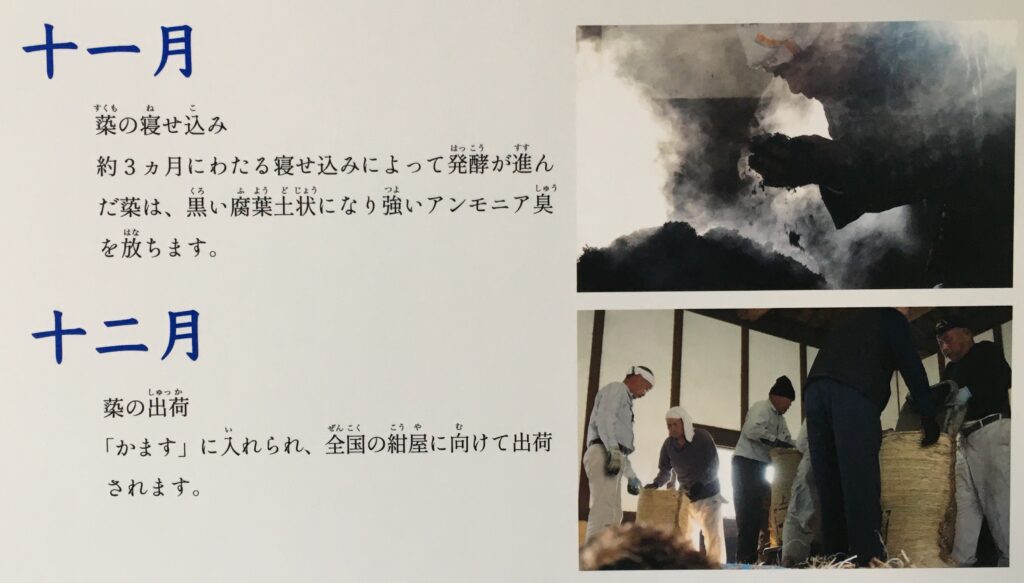

November: The sukumo, which has been fermenting for over 3 months starts to look like black humus and gives off a strong smell of ammonia.

December: Sukumo shipping. The skumo is placed in containers called kamasu, and are ready ot be shipped out to dyers around the country.

Above image is the actual Sukumo in fermentation chamber (寝床/sleeping room) at the Waza-no-Yakata. This photo was taken in January, and most of the fermentation process is already finished and it is not as active/warm as the peak of the fermentation process. The straw “blanket” is covering the sukumo so that it does not get cold in the winter climate.

The first weeks of sukumo fermentation process, it produces a very strong ammonia smell. It also heats up to 70 degrees and you will see steam coming out from it. A person from the Waza-no-yakata who guided us said the whole room was filled with steam and it was hard to even open one’s eyes as it gets filled with intense ammonia steam when the fermentation is at its peak. Imagining the makers of Sukumo has to mix the sukumo in ammonia steam every 5-7 days for the 100 days of fermentation period… it is a hard work to get this dye.

This is the “fresh” sukumo. It smells a bit like ammonia, but not so strong. It is still wet like soil. At this point the fermentation is still mildly going. After it is packed in straw bags of 50kg the fermentation runs at a very slow pace and in a few months it gets covered with white fungi. One can use it before it is covered with white fungi, or wait until the white fungi goes away, which is recommended (it colors even stronger after the white fungi, it says)

We could not see the actual Sukumo making process as most of it takes place in Oct-Dec. Here are some videos that shows the process.