I brought a lot of bend sensors made of a kinesiology tape, a type of sports tape. You can tape this sensor directly on skin. It is great for quick prototyping, and also quick to make. Here are step by step tutorials of how to make a kinesiology bend sensor.

You can find different designs of this sensor and design elaborations here >> https://www.kobakant.at/DIY/?p=8497

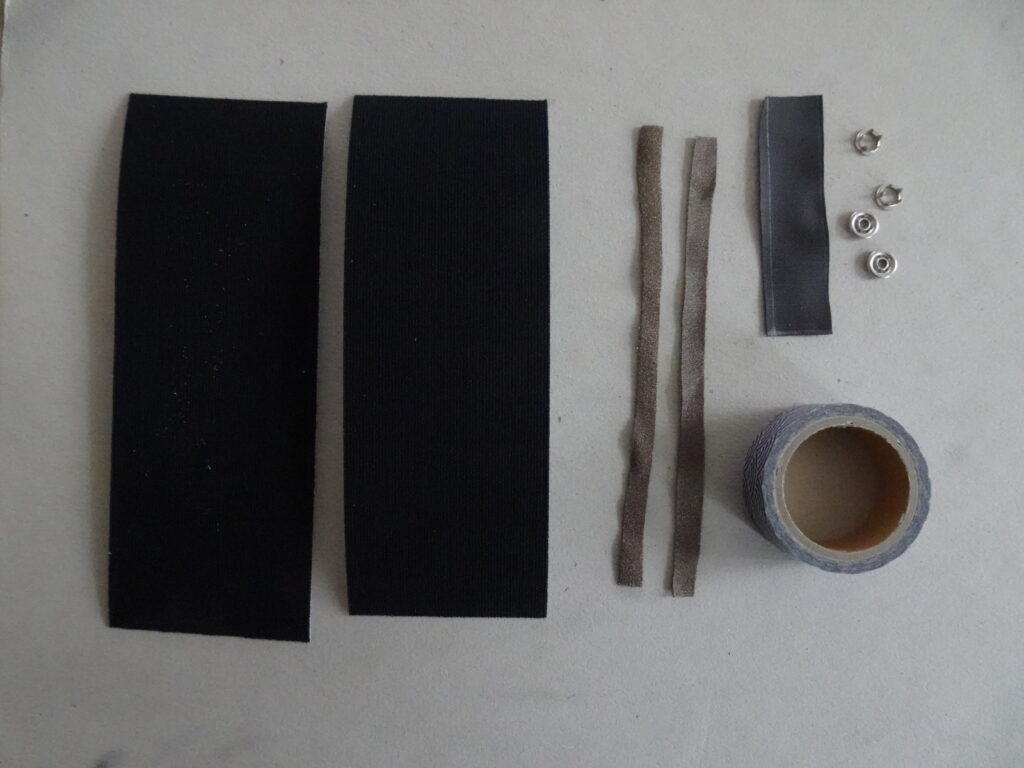

The basic material is above. 2 pieces of kenesiology tape, 2 long strip of stretch conductive fabric (stretch one is better if you want the sensor to be stretchy), eeonyx stretch fabric. In this example I used 7mm snaps to create a connection to fabric cables. You can use other method of connection if you do not have snaps. and lastly some kind of sticky tape to fix the kinesiology tape on your work surface while working. This makes it easier to work with it.

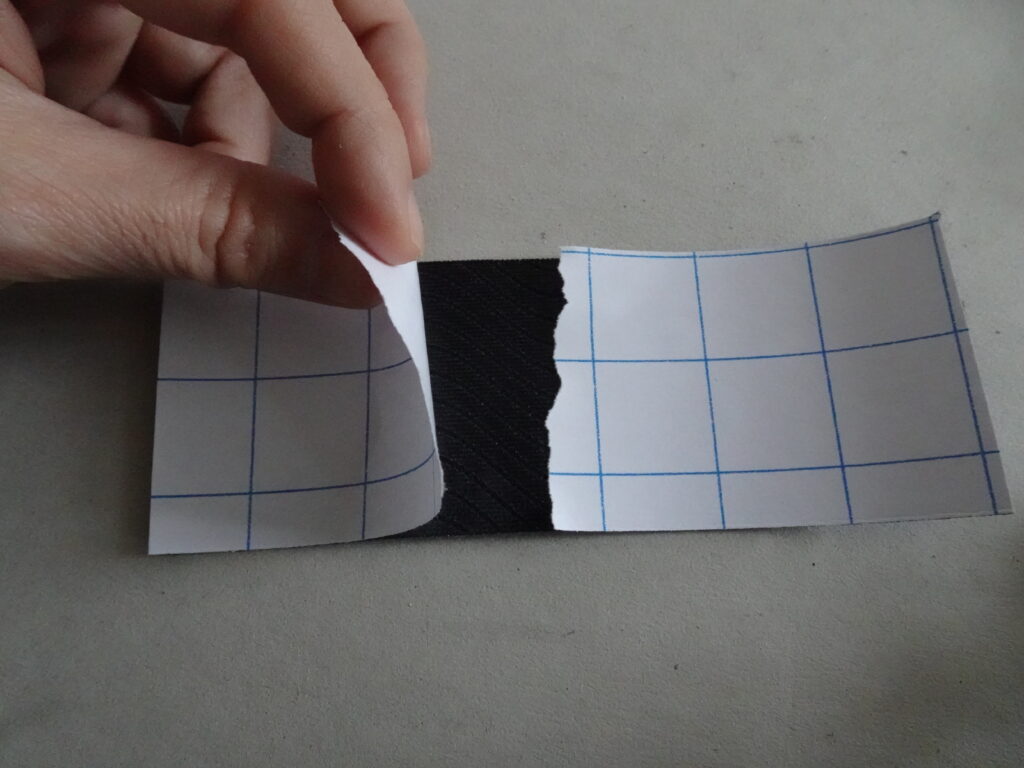

Stick any sticky tape in ring shape onto your work surface and stick the non sticky side of the kinesiology tape so it is fixed on your work surface with sticky side up. Remove the backing paper from the kinesiology tape.

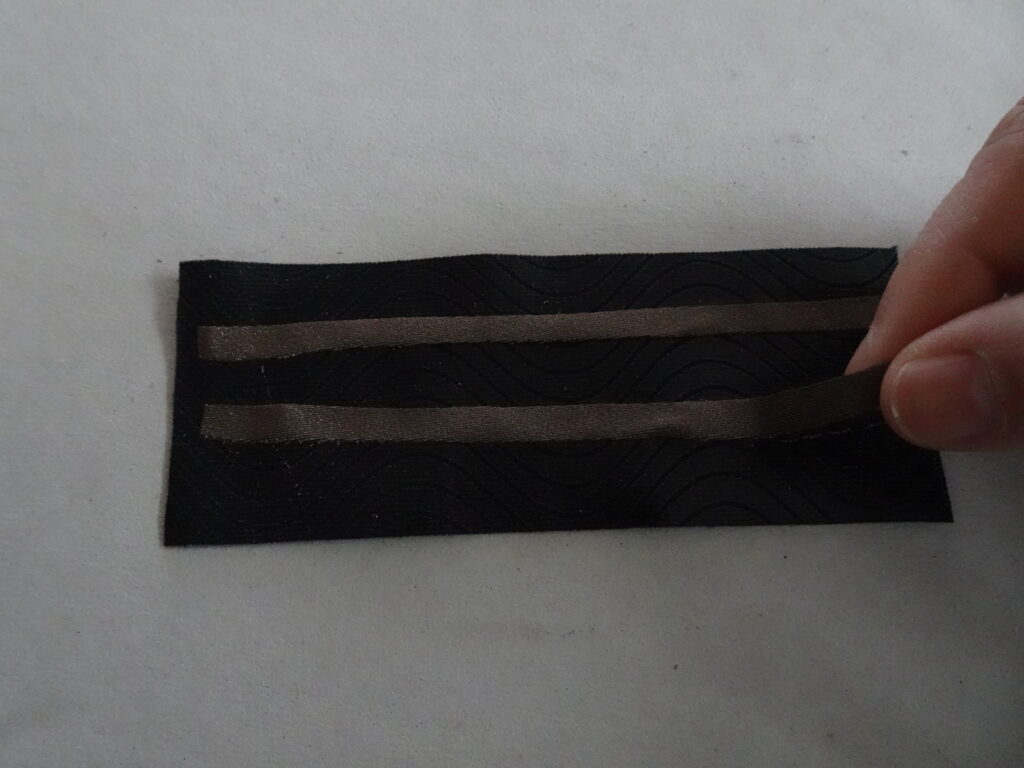

Place 2 stretch conductive fabric strip on the tape. Make sure they do not touch each other. The gap should be narrower than the resistive fabric piece. Then place the eeonyx resistive fabric on them. Make sure that resistive fabric touches both of the conductive strip. Electricity should flow through the resistive fabric between the two strip.

Peel off half of the second kinesiology tape’s backing paper and stick it on the layer just created with the sticky side down. Both of the tapes sticky side should be facing to each other. The outer side is both non-sticky side of the tape.

Trim down the shape of the tape to your desired shape. As I later want to stick them on skin with the same width kinesiology tape, I trim the sensor narrower. The edge is curved so it is easier to remove from the tape after the use.

Mark where you want to place the connector and press the snap. The sensor does not have polarity as it is a piece of resistive material. You can use any combination of snap directions (in above example, I used two 凹 snaps) . It is probably a good idea to keep some consistence rules when you make sensors or fabric circuit that uses same kind of snap press so they are interchangeable.